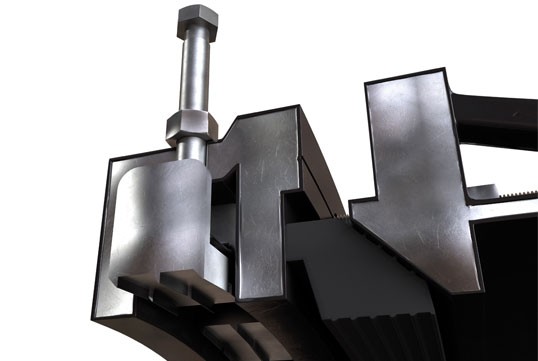

UltraGrip Amplified Coupling

The extension to the proven UltraGrip range of wide tolerance restrained fittings now includes DN700, DN800, DN900 and DN1000 sizes, which are ideal for new lay and large scale infrastructure projects.

All adaptors and couplings in the Amplified range are rated 16 bar, plus there is a full set of 2D and 3D CAD and BIM models.

The UltraGrip restraint system is equipped with a unique sealing and gripping technology that allows water utilities contractors to repair pipelines faster, without the need for external restraints, like for example thrust blocks.

When pipes are distorted or out of round the UltraGrip’s market leading 35mm tolerance provides more clearance to ensure a simple connection.

4° angularity at each end covering the entire range including top and bottom tolerance. This feature eliminates the need for installers to measure the pipe to calculate the allowable angularity.

View Full Amplified Benefits Explore Features in 3D

Wish to find out more about the UltraGrip Amplified range?

Data Sheets

- 1. UltraGrip Amplified Couplings DN700 - 800 Datasheet (11-2025) Download > (PDF)

- 2. UltraGrip Amplified Couplings DN900 Datasheet (11-2025) Download > (PDF)

- 3. UltraGrip Amplified Couplings DN1000 Datasheet (11-2025) Download > (PDF)

- 4. UltraGrip Amplified Support Liners DN700 - DN1000 Datasheet (11-2025) Download > (PDF)

Fitting Instructions

-

UltraGrip Amplified Coupling & Reducing Coupling Installation Manual DN700 - DN800 (18-09-2024)

UltraGrip Amplified Coupling & Reducing Coupling Installation Manual DN700 - DN800 (18-09-2024)

Download -

UltraGrip Amplified Coupling, Reducing Couplings & Flange Adaptors Installation Manual DN900 (04-2025)

UltraGrip Amplified Coupling, Reducing Couplings & Flange Adaptors Installation Manual DN900 (04-2025)

Download -

UltraGrip Amplified Coupling & Flange Adaptors Installation Manual DN1000 (02-2026)

UltraGrip Amplified Coupling & Flange Adaptors Installation Manual DN1000 (02-2026)

Download

General Videos

-

UltraGrip Amplified For Infrastructure Projects

View the Video -

UltraGrip Amplified For Repair & Maintenance Projects

View the Video

BIM Files

- 1. UltraGrip Amplified Coupling BIM View

CAD Drawings

Zip files contain DWG, DXF & PDF files

Certifications

- 1. WRc Certification - UltraGrip Amplified Coupling & Flange Adaptors Download >

Additional Downloads

- UltraGrip Amplified UK Fast Movers - Product Codes Download > (PDF)