Expansion Joint Selection

- The simplicity and versatility of the fittings make them suitable for many applications including pumping stations, water treatment works, sewage treatment works, plant rooms, meter chambers, power generation equipment, gas distribution stations.

- Viking Johnson’s Dismantling Joints are particularly suitable for simplifying the installation & removal of isolation valves, control valves, check valves, non-return valves, flow metering valves, pump sets, pressure reducing valves, flanged pipe & fittings.

- Designed and manufactured to BS EN ISO 9001: 2008 and tested to the most exacting requirements of WRAS (Water Regulatory Advisory Scheme) for use with potable water.

For the selection of the most suitable PosiFlex expansion joint, the following basic criteria must be determined:

Size – joint nominal bore size, required face-to-face length and mating flange size/specification.

Pressure – operating, design, surge and test pressure of the system

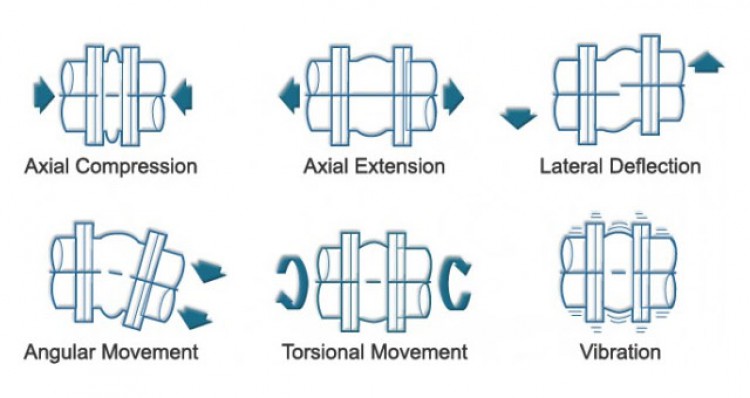

Movement – axial, lateral, angular, and torsional (if applicable)

Medium – type of fluid, air, gas or powder

Temperature – minimum and maximum range

PED requirements – Group 1-2 liquid, Group 1-2 as, SEP, CAT 1. (EU applications only)

1. Size

PosiFlex expansion joints are available in sizes from 25mm (1”) nominal bore up to of approximately 3600mm (144"). NB. Special, larger sizes available on application, with dimensions available on request.

2. Pressure

When making any design calculations on PosiFlex expansion joints it is important to consider the maximum pressure of the system, not the operating pressure. This could be either surge or test pressure. Remember that pressure may be positive or negative (vacuum).

The pressure capabilities of a PosiFlex joint are limited by the reinforcement of the carcass at the arch area. Standard pressure ratings exist for each style of PosiFlex expansion joint. If requirements exceed these ratings, special constructions are available on request. Standard face-to-face dimensions of the joints are detailed on the technical datasheets, other non standard dimensions available on request.

3. Movement

PosiFlex expansion joints are designed to accommodate axial (compression and elongation), lateral, angular and torsion movements. All movement capabilities are dependent upon the size and number of arches. For increased movement capability, more arches can be added (up to a maximum of four for most sizes).

4. Medium

The medium conveyed through the PosiFlex expansion joint can be fluid, gaseous or powder. The tube material of the joint must be compatible with the medium it is carrying. Abrasive materials may require a thicker and/or softer tube to improve service life. Note that in some cases the surrounding environment must be considered. The outer cover may be exposed to oils, chemicals, acid fumes or sunlight. Refer to chemical resistance tables to select the correct tube and cover elastomers. Remember that temperature considerations must be taken into account when selecting elastomers.

5. Temperature

Temperature ratings of expansion joints are governed by the materials of construction. Please contact PosiFlex for details.

6. Pressure Equipment Directive (PED) Regulations 1999

The PosiFlex expansion joint is interpreted as being defined as a pressure accessory within the Pressure Equipment Regulations 1999.

For the purposes of defining the product classification, expansion joints are considered as piping, not vessel, where the nominal size DN is more appropriate than the volume. Therefore for group 2 liquids for pressures above 0.5bar up to and including 10bar for all sizes, the classification is SEP (Sound Engineering Practices) and therefore cannot bear the CE mark.

Against this requirement PosiFlex products are designed and manufactured under ISO 9000 quality management systems to sound engineering practices. Additionally the products are marked for manufacturer identification and traceability and are accompanied by appropriate fitting instructions.